Key Features of 6×36 Wire Rope

1. Strand Construction and Flexibility of 6×36 Wire Rope

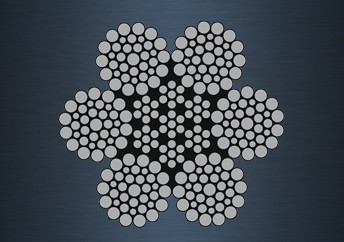

The 6×36 wire rope configuration consists of 6 strands, each made up of 36 individual wires, typically arranged in Seale, Warrington, or filler wire patterns. This dense composition provides excellent flexibility while maintaining core strength for dynamic marine applications.

2. Core Types and Structural Stability of 6×36 Wire Rope

Available with either a fiber core (FC) or independent wire rope core (IWRC), the 6×36 wire rope offers tailored performance. IWRC enhances strength and crush resistance, while FC improves flexibility and reduces weight.

3. Material and Corrosion Protection of 6×36 Wire Ropes

Manufacturers produce this rope using galvanized or stainless steel to resist corrosion in salt-laden environments. Lubrication is applied during manufacture to protect internal wires from moisture and wear during use.

4. Tensile Strength and Load Capacity of 6×36 Wire Ropes

This wire rope supports high breaking loads while allowing smooth spooling under load. Its structure absorbs shock loads and is ideal for use on deck machinery, lifting gear, and cargo-handling systems under constant tension.

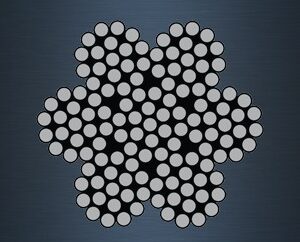

5. Bending Fatigue Resistance of 6×36 Wire Rope

The fine-wire construction and uniform strand distribution provide excellent fatigue resistance over pulleys, sheaves, and drums. It’s especially suitable for repetitive lifting operations where flexibility and endurance are critical.

6. Diameter Range and Customization

Available in diameters from 6 mm to over 60 mm, the 6×36 rope can be customized for length, end fittings (thimbles, sockets, clips), and coatings based on application needs and vessel requirements.

7. Installation and Handling

Crews can install this rope using standard marine rigging equipment. Its flexible structure allows for easy reeving and spooling, while its lubrication aids in minimizing friction during operation.

8. Compliance and Certifications

All 6×36 wire ropes meet ISO 2408, API, and EN standards for steel wire ropes. Products are approved by DNV, ABS, and Lloyd’s Register for use in critical lifting and mooring systems on marine vessels.

Construction:

-

Strand Configuration: 6×36 (Total of 216 wires)

-

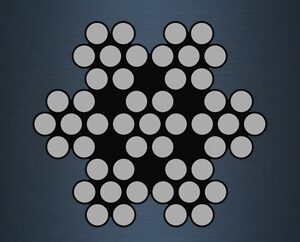

Core Types:

-

Fiber Core (FC) – for enhanced flexibility

-

Independent Wire Rope Core (IWRC) – for higher strength and durability

-

-

Material Options:

-

Galvanized Steel (for corrosion resistance)

-

AISI 316 Stainless Steel (for marine environments)

-

Ungalvanized (for indoor/heavy static applications)

-

Finish: Bright, Zinc Coated (Galvanized), or Polished Stainless

Available Variants:

-

-

6×36 FC (Fiber Core) – More flexible, suitable for sheaves and tight bends

-

6×36 IWRC (Steel Core) – Higher strength and crush resistance

-

Galvanized or Stainless Steel Finishes

-

PVC-Coated Options – Available on request

-

Pre-fabricated Lifting Slings & Assemblies

-