Key Features of Marine Fairleads:

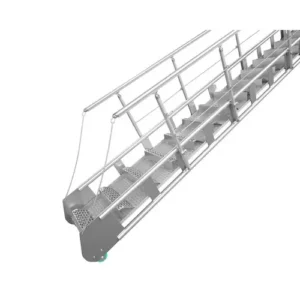

- Design and Construction:

- Material: Typically made from strong, corrosion-resistant materials such as stainless steel, aluminum, or cast iron. These materials are chosen for their durability and ability to withstand harsh marine environments.

- Shape: Fairleads often have a U-shaped, round, or rectangular design with smooth, curved surfaces to minimize friction and wear on the lines. The design may also include rollers or sheaves to facilitate smooth passage of the lines.

- Mounting: Fairleads are generally mounted on docks, piers, or the hull of a ship. They may be bolted or welded in place, depending on the installation requirements.

- Types:

- Fixed Fairleads: Permanently mounted fairleads that provide a fixed guiding point for lines. They are used in situations where lines need to be directed in a specific path.

- Rolling Fairleads: Equipped with rollers or sheaves that allow the line to move more freely and reduce friction. These are often used in high-load applications where smooth line movement is critical.

- Adjustable Fairleads: Designed to be adjustable in position or angle, allowing for flexibility in guiding lines based on operational needs.

- Chain Fairleads: Feature a series of linked chains or plates that guide and protect mooring chains or heavy cables.

- Applications:

- Dock and Pier Operations: Used to guide mooring lines and ropes during vessel docking and berthing. Helps in managing the direction and tension of the lines, reducing wear and preventing tangling.

- Shipboard Operations: Installed on ships to guide lines such as anchor chains, mooring lines, and cargo handling ropes. Ensures smooth operation and reduces the risk of line damage.

- Marine and Offshore Platforms: Employed on floating platforms, oil rigs, and other offshore structures to manage the movement of heavy cables and lines.

- Performance and Benefits:

- Line Guidance: Provides a controlled path for ropes and cables, helping to manage their direction and prevent misalignment or tangling.

- Wear Reduction: Smooth surfaces and rollers reduce friction and wear on the lines, extending their service life and improving performance.

- Durability: Constructed from robust materials designed to withstand marine conditions, including exposure to saltwater, UV rays, and physical stress.

- Maintenance and Care:

- Inspection: Regularly inspect fairleads for signs of wear, corrosion, or damage. Check the mounting hardware and moving parts (if applicable) for integrity.

- Cleaning: Clean the fairleads to remove debris, marine growth, or contaminants that could affect their performance or appearance.

- Repairs: Address any damage or issues promptly to ensure the fairleads remain functional and safe for use. This may involve repairing or replacing components as needed.

- Safety Considerations:

- Load Capacity: Ensure that the fairleads are rated for the specific loads and types of lines they will be handling. Overloading can cause damage or failure.

- Proper Installation: Ensure fairleads are securely mounted and positioned to provide effective guidance and support for lines.

- Line Management: Use appropriate line sizes and types for the fairleads to ensure proper fit and performance.

Advantages of Marine Fairleads:

- Effective Line Control: Helps guide and manage ropes, cables, and mooring lines, reducing the risk of tangling, wear, or damage.

- Durability: Built to withstand harsh marine conditions and heavy loads, making them suitable for long-term use in various maritime applications.

- Smooth Operation: Smooth surfaces and rollers facilitate the free movement of lines, improving operational efficiency.

Considerations for Marine Fairleads:

- Selection: Choose the appropriate type, size, and material of fairlead based on the specific needs of the maritime operation and the type of lines being used.

- Corrosion Protection: Ensure fairleads are treated or coated to resist corrosion and extend their lifespan in marine environments.

- Compliance: Follow relevant industry standards and regulations for the design, installation, and maintenance of fairleads to ensure safety and performance.

Marine fairleads are essential components for managing the movement of lines and cables in marine operations, providing effective guidance and protection to ensure safe and efficient berthing, mooring, and handling of maritime equipment.