Key Features of Smit Brackets:

- Design and Construction:

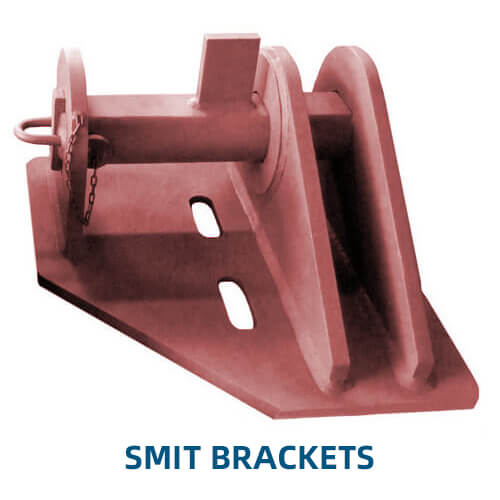

- Brackets: Smit brackets are heavy-duty, forged steel components typically designed with a rounded or flared mouth to guide and secure the towing line or chain. The design helps to distribute the load evenly and reduces stress on the bracket.

- Material: Made from high-strength steel, often with a galvanized or corrosion-resistant coating to withstand harsh marine environments. The material choice ensures durability and long service life under heavy loads.

- Mounting: Smit brackets are welded or bolted onto the deck or hull of the vessel. They are positioned to align with the vessel’s towing arrangement, ensuring effective load distribution during towing operations.

- Types:

- Standard Smit Brackets: These are the typical brackets used on many vessels, designed for general towing and anchoring purposes.

- Customized Smit Brackets: Some vessels require customized designs to accommodate specific towing or operational needs. These might include variations in size, load capacity, or attachment methods.

- Applications:

- Towing Operations: Smit brackets are primarily used to secure towing lines on ships, especially during tugboat operations. They provide a strong and reliable attachment point that can handle the significant forces involved in towing large vessels.

- Offshore Vessels: Used on offshore supply vessels (OSVs), anchor handling tug supply (AHTS) vessels, and other specialized ships. The brackets are crucial for managing the complex towing and anchoring operations typical in offshore environments.

- Heavy Cargo Ships: Smit brackets are also found on large cargo ships, where they are used to secure towing lines during harbor maneuvers or emergency towing situations.

- Performance and Benefits:

- High Load Capacity: Smit brackets are designed to handle extremely high loads, making them suitable for heavy-duty towing operations.

- Durability: Constructed from high-strength steel and designed to resist corrosion and wear, these brackets offer long-term reliability in challenging marine conditions.

- Safety: By providing a secure and stable attachment point, Smit brackets help to enhance the safety of towing operations, reducing the risk of line failure or vessel damage.

- Maintenance and Care:

- Inspection: Regularly inspect Smit brackets for signs of wear, corrosion, or structural damage. Pay close attention to the integrity of the welds or bolts securing the bracket to the vessel.

- Cleaning: Keep the brackets clean of marine growth, salt deposits, and other contaminants to prevent corrosion. Use appropriate cleaning methods to avoid damaging the surface coating.

- Lubrication: Although Smit brackets have no moving parts, it’s essential to ensure that any adjacent components (like shackles or towing lines) are well-maintained to prevent unnecessary wear on the brackets.

- Safety Considerations:

- Proper Installation: Ensure that Smit brackets are correctly installed according to the vessel’s specifications and aligned with towing arrangements to avoid undue stress during operations.

- Load Assessment: Always assess the load before engaging in towing operations to ensure that the bracket’s capacity is not exceeded.

- Emergency Preparedness: Regularly check the condition of Smit brackets as part of the vessel’s emergency preparedness, especially if the vessel operates in high-risk areas or under extreme conditions.

Advantages of Smit Brackets:

- Strength and Reliability: Known for their ability to handle heavy loads and provide a secure attachment point, making them indispensable in maritime towing operations.

- Durability: Engineered to resist the harsh conditions of marine environments, ensuring long service life.

- Versatility: Suitable for various vessels and operations, from towing to emergency anchoring.

Considerations for Smit Brackets:

- Selection: Choose the appropriate size and type of Smit bracket based on the vessel’s size, towing requirements, and operational conditions.

- Installation: Ensure proper installation and alignment to maximize the bracket’s performance and longevity.

- Compliance: Follow industry standards and regulations related to the use of Smit brackets in towing operations to ensure safety and compliance.

Smit brackets are critical components for the safe and efficient towing of vessels. Their robust design and ability to handle high loads make them essential for offshore and heavy-duty maritime operations, ensuring that vessels can be safely and securely towed in various conditions.