Key Features of Bulkhead Gearing Devices:

- Design and Construction:

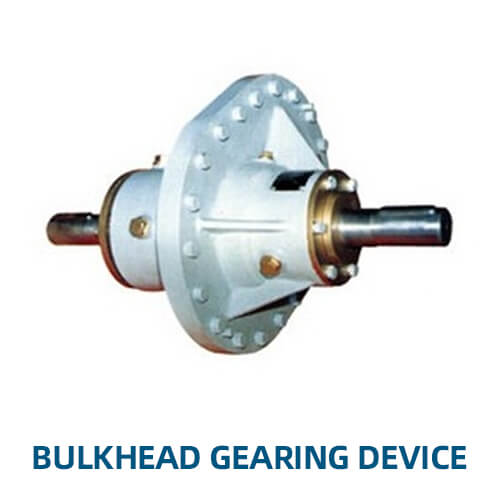

- Gear Mechanism: The core of the bulkhead gearing device is a gear assembly that translates rotational motion into linear or angular movement, depending on the specific application. This mechanism is often composed of high-strength gears, pinions, and shafts designed to withstand significant loads and operate smoothly.

- Control Handle: Bulkhead gearing devices are typically operated via a control handle or wheel located on the bulkhead. This handle allows for manual operation of the gears, enabling the user to open or close doors, valves, or other controlled components.

- Mounting: The device is securely mounted to the bulkhead, often in a location that is easily accessible during normal operations and emergencies. The mounting must be robust to ensure the device remains operational under stress or during a ship’s movement.

- Types:

- Manual Bulkhead Gearing Devices: Operated manually through a handle or wheel, these devices are reliable and do not rely on external power sources, making them ideal for emergency situations.

- Powered Bulkhead Gearing Devices: These are motorized versions that use hydraulic, electric, or pneumatic power to operate the gears. They are often used in larger or more complex systems where manual operation would be impractical.

- Watertight Door Gearing: Specifically designed for controlling watertight doors, these devices are critical for maintaining compartmental integrity in the event of flooding.

- Applications:

- Watertight Doors: Bulkhead gearing devices are commonly used to operate watertight doors in ships. These doors are crucial in preventing the spread of water between compartments in case of a hull breach or flooding.

- Valves and Hatches: They are also used to control valves and hatches that regulate the flow of fluids or gases within the ship. This can include fuel lines, ballast systems, or ventilation hatches.

- Safety Systems: In safety-critical systems, such as those controlling fire suppression or emergency ventilation, bulkhead gearing devices ensure that these systems can be quickly and reliably activated.

- Performance and Benefits:

- Reliability: Designed for use in harsh maritime environments, bulkhead gearing devices are built to be reliable under extreme conditions, including heavy seas, high loads, and emergency scenarios.

- Durability: Constructed from corrosion-resistant materials, such as stainless steel or high-grade alloys, these devices are meant to last, even with minimal maintenance.

- Precision Control: The gear mechanism allows for precise control of the connected system, whether it’s opening a heavy door or regulating a valve.

- Maintenance and Care:

- Regular Inspection: It’s important to inspect the gearing device regularly for signs of wear, corrosion, or mechanical failure. Regular checks help ensure the system remains operational when needed most.

- Lubrication: Ensure that all moving parts, particularly the gears and shafts, are properly lubricated to reduce friction and prevent wear. Use marine-grade lubricants to protect against saltwater and humidity.

- Operational Testing: Periodically test the device to ensure it functions correctly, particularly in emergency situations where immediate operation is critical.

- Safety Considerations:

- Proper Training: Ensure that all crew members are trained in the operation of the bulkhead gearing devices, including understanding the manual override in case of power failure in powered systems.

- Emergency Readiness: Regularly drill and test the system as part of the ship’s emergency preparedness to ensure it can be relied upon in critical situations.

- Load Capacity: Be aware of the load capacity of the device and ensure it is not exceeded, as overloading can cause mechanical failure.

Advantages of Bulkhead Gearing Devices:

- Critical for Safety: Bulkhead gearing devices are essential for maintaining the safety and integrity of a vessel, especially in emergency situations.

- Reliable Operation: These devices are designed to function under extreme conditions, ensuring that critical systems can be controlled when needed.

- Durable Construction: Made from robust materials, bulkhead gearing devices are built to withstand the harsh marine environment and provide long-term service.

Considerations for Bulkhead Gearing Devices:

- Installation: Proper installation is crucial to ensure the device operates correctly and securely. Installation should be performed according to manufacturer specifications and industry standards.

- Maintenance: Regular maintenance, including lubrication and inspection, is necessary to keep the device in working order.

- Compliance: Ensure that the bulkhead gearing device complies with relevant maritime safety standards and regulations, particularly those related to watertight integrity and emergency systems.

Bulkhead gearing devices are vital components in the safety and operational systems of marine vessels. Their design allows for the reliable control of watertight doors, valves, and hatches, ensuring that the ship can respond effectively to emergencies and maintain its structural integrity in challenging conditions.